Diecasting is now a major component of the manufacturing industry in Malaysia which has significantly aided in Malaysia’s growth in industry and economic growth. The precision casting process entails the injection of molten metal into a mold cavity using intense pressure, resulting in exquisitely designed, top-quality metal components. In the last few years the industry of diecasting in Malaysia has grown and developed due to the advancement of technology and a highly skilled workforce as well as the support of government policies. Its rapid growth highlights Malaysia’s ambition to be a major player on the world of manufacturing, making high-end components for diverse industries such as electronics, automotive, as well as consumer goods.

Diecasting’s development in Malaysia is found in the late 20th century. It was also the time that saw Malaysia’s efforts to industrialize. In the beginning, diecasting was used to make simple parts of metal that could be used for domestic purposes. But as the economy of Malaysia expanded and became industrialized, the need for higher-precision and more intricate diecasting components grew. The demand for this was especially high in the electronics and automotive sectors, that required stable high-quality, durable parts to make their products. With diecasting’s potential to increase manufacturing productivity and increase productivity, the Malaysian government came up with strategies to encourage development of the industry, such as investing in the latest infrastructure as well as technology, which created the environment that encourages the development of innovation and growth.

Technology advancements have been instrumental in driving Malaysia’s diecasting industry to the next level. The merging of computer-aided design (CAD) and computer-aided production (CAM) techniques has completely transformed the process of diecasting, providing more precision, efficiency as well as greater complexity when designing parts as well as production. Diecasting methods that are modern like squeeze casting and vacuum diecasting has further enhanced the performance and longevity of the diecast components. Furthermore, advances in materials research have resulted in the creation of alloys that have improved properties, expanding the range of uses for components made of diecast. This technological improvement has enabled Malaysian diecasting companies to comply with strict international standards for quality and position them as highly top players on the global market.

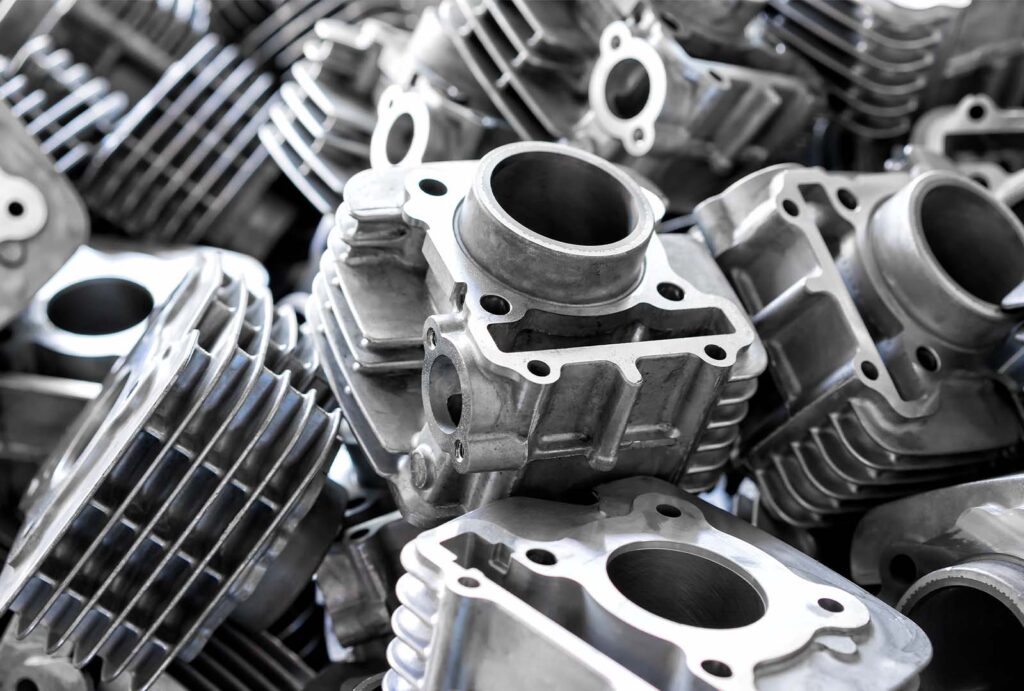

The automobile industry is one of the main customers of Malaysia’s capabilities in diecasting. Diecast parts are vital to manufacture various automotive parts which include engines, transmission cases and structural components. Their precision and dependability of these components make them suitable for the automotive industry in which durability and performance is paramount. Malaysia’s strategically located location and developed infrastructure have drawn a number of international automotive companies, further increasing demand for components made of diecast. In the end, Malaysia is now an essential participant in the supply chain for automotive components, using its expertise in diecasting to aid the development of the industry as well as keep up with the ever-changing requirements of auto manufacturers across the globe.

In addition to the automobile industry Electronics industry heavily depends on diecasting when making intricate and exact components. Diecasting can be used for the production of components like electronics housings and connectors as well as heat sinks. A rapidly expanding electronics consumer market, fueled by a growing demand for electronic devices including tablets, smartphones and laptops, has provided substantial possibilities to Nickel chrome plating Malaysia. With the high standards of production and using advanced manufacturing techniques, Malaysia has positioned itself as a trusted manufacturer of diecast components for the electronics industry worldwide. This is a testament to the flexibility and flexibility of Malaysia’s diecasting sector to meet the diverse requirements of the high-tech industry as well as contributing to Malaysia’s economic growth.

In the near in the future, prospects for Malaysia’s diecasting sector are positive. The shift to lighter and energy-efficient cars is predicted to fuel the need for diecast aluminum parts for the automotive industry. Additionally, the continuous growth of the electronics sector opens up new possibilities for diecasters. To take advantage of these opportunities, Malaysian diecasters must continue to invest in technology as well as sustainability. Making production more efficient and less environmental impacts will be vital to ensure their competitiveness. A continued support from the government in research and development and a favourable business climate, is crucial to sustain the industry’s expansion. If Malaysia takes advantage of these opportunities, Malaysia is able to further strengthen its standing as a key participant in the worldwide diecasting market. This will drive technological advancement and economic growth.

Diecasting, in the end, is now a vital part of Malaysia’s manufacturing landscape and is the driving force behind the expansion of important sectors like electronics and automobiles. Diecasting’s evolution as an sector, driven by advancements in technology and strategic plans have enabled Malaysia to be competitive globally. The demand for premium diecast parts continues to increase The prospects for diecasting in Malaysia is looking promising. With the right investments in new technology while maintaining high standards and making sure that they are sustainable, Malaysian diecasters can seize the new opportunities, and significantly contribute in the nation’s economic growth. Diecasting’s journey in Malaysia is an example of the country’s dedication to excellence in manufacturing and technological advancement, and highlighting its position as an engine for the growth of industry and innovating.